Streamlining Supply Chain Processes for Quick Client Approvals and Efficient Production

- Myungjun Kim

- Oct 18

- 3 min read

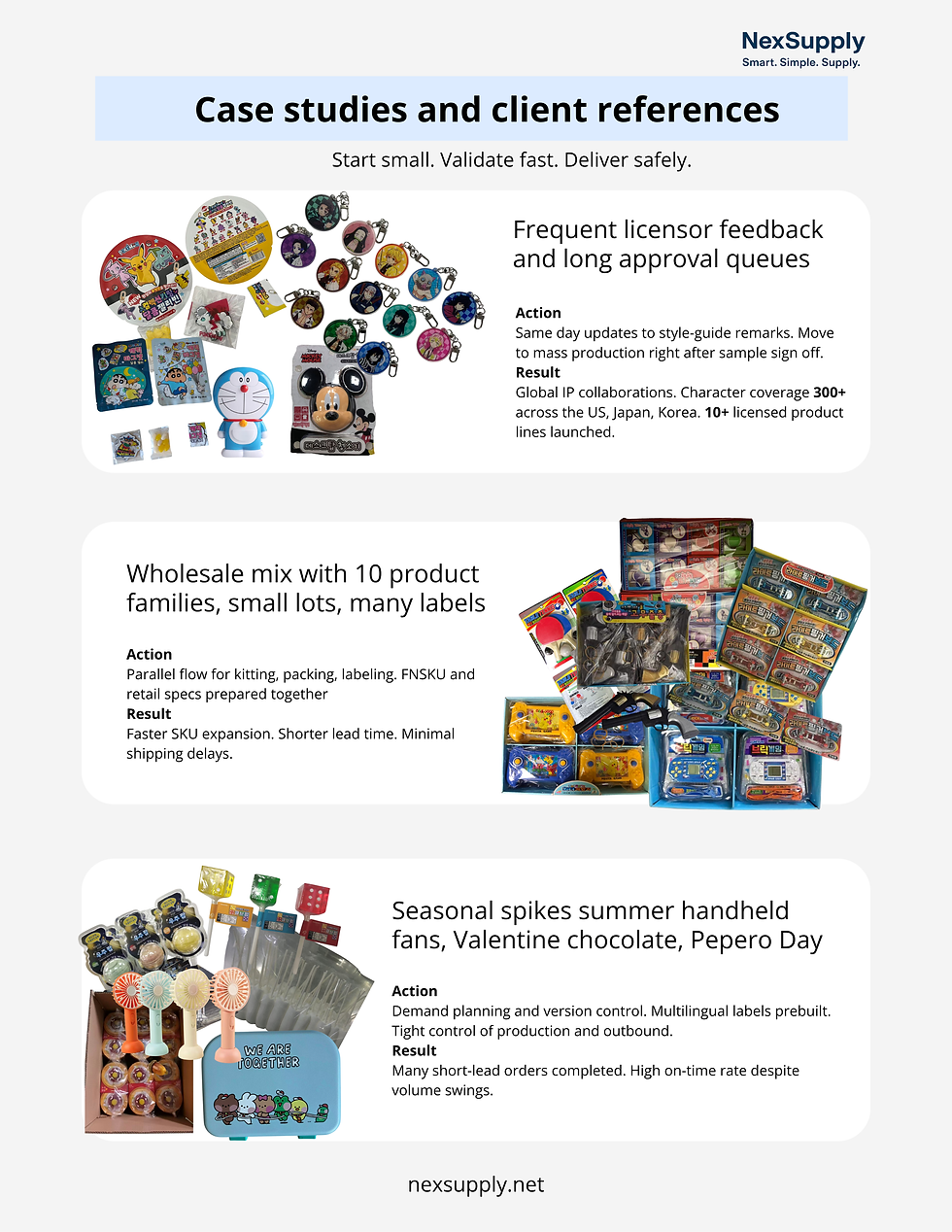

In today's fast-moving retail world, being able to quickly adapt to market demands is essential. Companies are eager to enhance their supply chain operations to guarantee timely product delivery and satisfied clients. This article discusses practical strategies for securing quick client approvals and improving production efficiency, emphasizing the roles of validation, licensor approvals, and parallel processing.

The Importance of Starting Small

Launching a new product can be daunting, but starting small can be highly effective. Focusing on a limited initial offering allows businesses to quickly validate their ideas and collect feedback from clients. This strategy reduces risk and makes it easier to make necessary changes before expanding production.

For example, a company introducing a new snack might first launch a single flavor in a selected market. This approach helps gauge customer interest without the resources needed for multiple flavors. Businesses can then refine their offerings based on initial sales data and customer responses before scaling up to produce a full range of flavors.

Starting small also means companies can manage their resources better. Testing with smaller production runs decreases waste and ensures that the product meets client needs before a larger launch.

Validating Fast for Client Confidence

Validation is key in the product development journey. Clients want reassurance that their investment will yield positive returns. Rapid validation techniques can help give clients the confidence to move forward.

A noteworthy method is providing same-day updates during the licensor approval process. For instance, if a business is working with a licensor on a branded product, sharing status updates every day can enhance transparency and build trust. Reducing the average approval cycle time from weeks to days can enable businesses to shift to mass production almost immediately after receiving the necessary sign-offs.

Efficient Production Through Parallel Kitting and Labeling

After a product has been validated, ensuring efficient production is crucial. One effective way to do this is through parallel kitting and labeling. This process allows companies to prepare multiple components at once, which can significantly reduce lead times.

For instance, if a business is preparing a set of promotional items for a trade show that includes T-shirts, mugs, and bags, kitting these items in parallel ensures they can be shipped quickly once approved. During peak times, such as holiday seasons, this approach gets widely demanded items, like toys and gadgets, to market promptly, meeting customer expectations.

Adapting to Seasonal Spikes

When demand surges seasonally, it can challenge supply chain management. However, with the right strategies, businesses can effectively handle these fluctuations. Using parallel kitting and labeling allows companies to quickly ramp up production to meet increased demands.

Additionally, clear communication with clients is vital during busy periods. Regular updates on production status and realistic timelines can help calm client worries and ensure a seamless supply chain operation.

The Power of Visual Communication

Visual communication can greatly enhance product development and supply chain processes. Sending images or mock-ups of the product helps clients visualize the final outcome, leading to more effective feedback.

For example, presenting a prototype box can spark client interest and excitement. Businesses that take this step are often more successful in moving forward with larger orders because clients can see and touch a tangible representation of what they are investing in.

Final Thoughts: Delivering Safely and Efficiently

Streamlining supply chain processes is vital for achieving quick client approvals and efficient production. By starting small, validating rapidly, and using parallel kitting and labeling, companies can improve operational efficiency and respond effectively to market demands.

As the retail landscape evolves, businesses must remain flexible and proactive. By applying these strategies, companies can not only meet client expectations but also ensure timely product delivery.

In a marketplace where speed and quality matter, embracing these practices can give a company a competitive edge. The path from idea to delivery might be challenging, but with the right strategies in place, it can also bring significant rewards.

Comments